TRAY THERMOSEALERS MACHINES

The OTM thermosealers are automatic in-line machines for trays packaging which are capable of working both in vacuum and in modified atmosphere. They are also able to work with the SKINeffect with and without product protrusion.

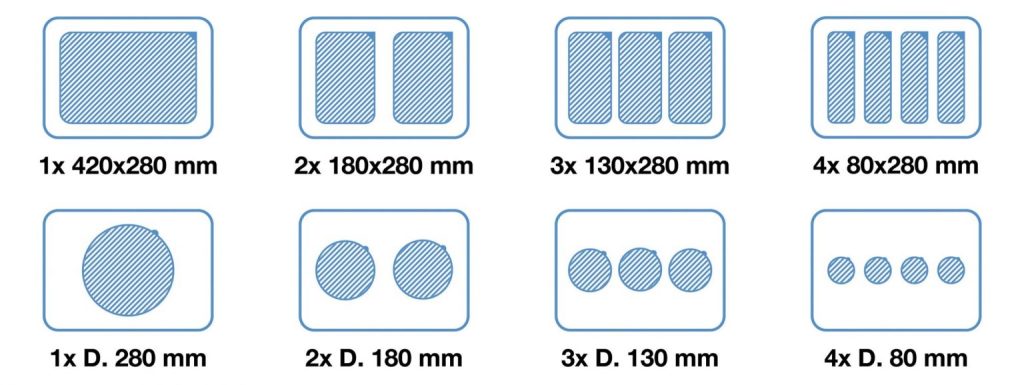

Any kind of trays can be packed, with easy and quick mould changes, without the use of tools.

The constant thermoregulation of the sealing temperature guarantees for the maximum safety and precision.

The practical and intuitive 7’’ touch-screen display facilitates the introduction of work parameters, the management of the various functions and the display of messages and eventual alarms.

PLC with Ethernet connection allows interfacing the machine parameters with company systems.

Despite the compact dimensions that facilitate their integration in workplaces, the OTM series are designed for the heaviest uses with the utmost reliability : the structure of the machine is completely in stainless steel AISI 304, with an electrical panel in IP66 / NEMA 4 insulation class.

Full line